When a new drug is developed it does through many stages of testing, including that on animals. This has always been a controversial topic and many organizations are moving away from the practice. One of the biggest contributions biotechnology has made to ease this transition is by introducing 3D printers that can fabricate biological tissues.

The technique allows companies to manufacture the specific type of human tissue they require for testing their medication. It was even used to make small model pancreas recently.

Faster 3D printing technology

However, usually, the process of printing these tissues takes a very long time. This is why a team from the University of California San Diego has designed a printer that only takes 10 seconds to print one sample. It is called the high throughput 3D bioprinter (HT3DP). Not only is it fast, but it also prints the tissues with perfect accuracy. It can even undertake complex structures such as cancer tissues with attached blood vessels.

Another important feature of this technology is the fact that it prints the samples directly into the well plates. Therefore, they don’t have to be manually transferred like the previous methods.

According to Shaochen Chen, a professor of nano-engineering at the UC San Diego Jacobs School of Engineering, this is a marked improvement. “When you’re scaling this up to a 96-well plate, you’re talking about a world of difference in time savings—at least 96 hours using a traditional method plus sample transfer time, versus around 30 minutes total with our technology.”

How does it work?

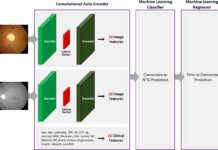

The technology works like this: the researchers first make a digitized 3D model of the tissue they want to print. The design can also be made using a patient’s medical scan to fit their needs. Then, a computer breaks these models into 2D images and mounts them over microscopic mirrors which project light patterns on the cell cultures which are suspended in light-activated polymers which solidify around the cells in specific molds so that the cells grow into tissues accordingly.

“An analogy would be comparing the difference between drawing a shape using a pencil versus a stamp. With a pencil, you’d have to draw every single line until you complete the shape. But with a stamp, you mark that entire shape all at once. That’s what the digital micromirror device does in our technology. It’s orders of magnitude difference in speed.” – Henry Hwang, a Ph.D. student of nanoengineering and co-first author of the study.

Source: UC San Diego Jacobs School of Engineering

https://jacobsschool.ucsd.edu/news/release/3290