Bioprinting is more than just a speedy means to create physical items. It also allows researchers to create duplicates of human tissue that can be utilised to improve human health. Thereby constructing organs for transplantation, analysing disease development, and testing novel medications. While researchers have made progress over the years. Limited available technologies have restricted the area, incapable of printing tissues with high cell density at scale.

Penn State researchers have devised a revolutionary bioprinting technology that uses spheroids, or cell clusters, to build complex tissue. This innovative process enhances the precision and scalability of tissue production, creating tissue ten times faster than previous methods. It paves the way for the development of functional tissues and organs. As well as advancements in regenerative medicine, according to the experts. The finding is published in Nature Communications.

Ibrahim T. Ozbolat, Dorothy Foehr Huck, and J. Lloyd Huck Chair said

This technique is a significant advancement in rapid bioprinting of spheroids. It enables the bioprinting of tissues in a high-throughput manner at a speed much faster than existing techniques with high cell viability.”

A 3D Printing

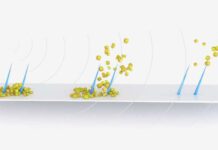

Bioprinting enables researchers to create 3D structures from living cells and other substances. Living cells are encased in a substrate, such as a hydrogel, to create bioink, which is then printed in layers with a specialized printer. These cells multiply and proliferate, eventually developing into 3D tissue over several weeks. Ozbolat compared it to building a brick wall, with the cells acting as the bricks. In addition, the bioink serves as the cement or mortar.

Ozbolat and his colleagues created an aspiration-assisted bioprinting technology in a prior study. Using a pipette tip, the researchers could pick up tiny balls of cells. And arrange them precisely where they would self-assemble and form solid tissue.

However, because the approach requires shifting spheroids one at a time. It could take days to construct a one-cubic-centimeter structure. To overcome these challenges, the researchers created a novel approach called the High-throughput Integrated Tissue Fabrication System for Bioprinting (HITS-Bio). HITS-Bio employs a digitally controlled nozzle array that moves in three dimensions, allowing researchers to manage several spheroids at the same time.

The scientists arranged the nozzles in a four-by-four array, allowing them to pick up 16 spheroids at once. And position them on a bioink substrate rapidly and precisely. The nozzle array may also pick up spheroids in bespoke patterns. That can then be repeated to mimic the architecture found in complex tissue.

According to Ozbolat, the HITS-Bio technology allows for the creation of complex and functioning tissue at a scalable level. Expanding the number of nozzles may result in the formation of larger and more intricate tissues, such as organs and organ tissue like the liver.